district heating with heat pumps utilizing low-temperature sources

We recently had the opportunity to meet with Brian Gaughan from Sabroe in Denmark. Sabroe is considered a pioneer in high-temperature heat pump technology and a leader in the sustainable use of ammonia as a refrigerant. The company, a manufacturer of industrial refrigeration and heat pump systems, focuses on delivering sustainable and energy-efficient solutions that are particularly suitable for district heating or replacing combined heat and power plants due to their high temperatures.

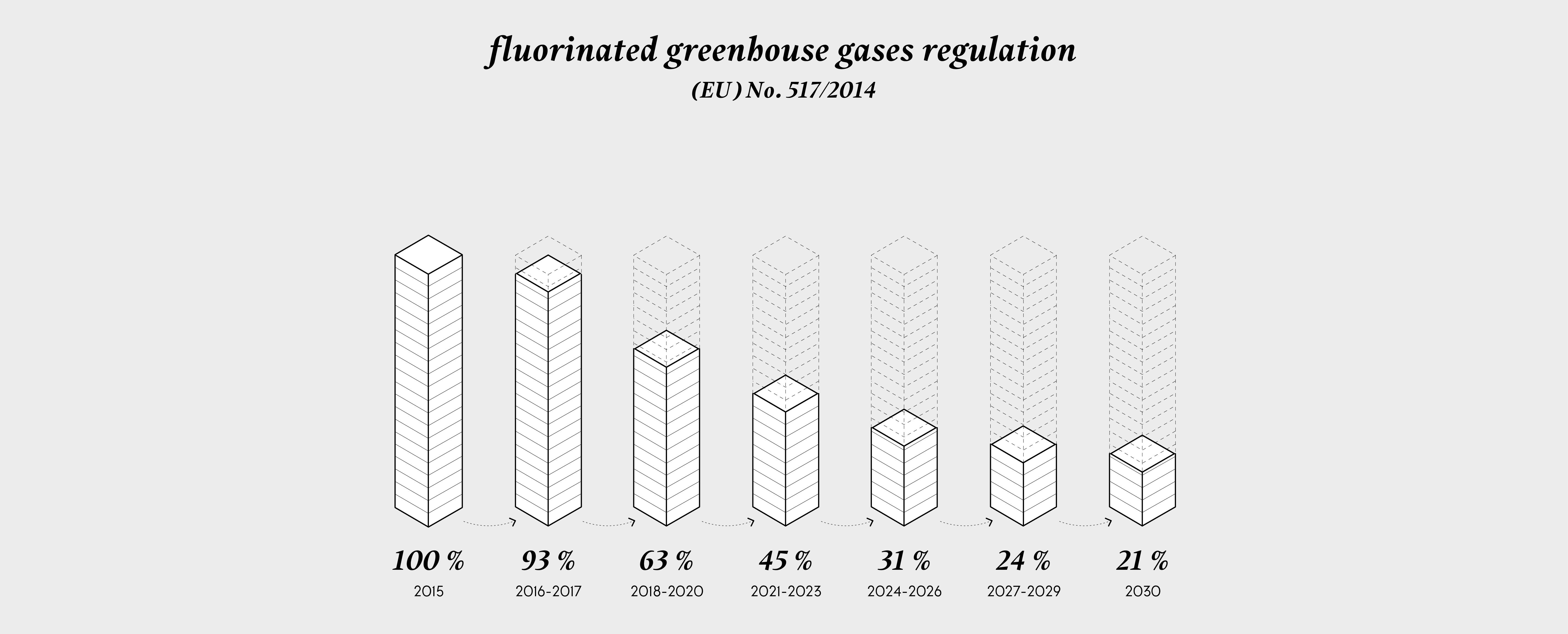

In this context, it is important to know that the EU has introduced a long-term strategy to reduce greenhouse gas emissions. Part of this strategy is the planned ban on synthetic refrigerants, also known as "F-gases", in heat pumps from 2024. These gases are potent greenhouse gases that can have significant impacts on the climate. The ban aims to accelerate the transition to more environmentally friendly, natural refrigerants.

These natural refrigerants, including ammonia, propane, and carbon dioxide, typically have much lower environmental impacts. However, the planned ban has raised concerns in the industry about the safety, efficiency, and cost of these natural refrigerants. The benefits of these refrigerants, especially their minimal impacts on the environment and climate, far outweigh the challenges.

Due to the concerns Sabroe severely reduced the ammonia charge by reinventing their heat exchanges. A system once needing 500kg only needs 70kg of ammonia and by this reduction of gas charge they vastly reduce the impact of a gas leak.

Brian Gaughan told me that a loss of ammonia will only need a small inexpensive top up. This reduces cost and labour for maintenance compared to f-gas refrigerants. F-gases are a blend of gasses, when a leak happens the least dense gases escape first rendering the blend ineffective and it necessary to dispose the whole system charge and replace with new gases.

The planned EU ban on synthetic refrigerants will undoubtedly bring about changes in the heat pump industry. Sabroe's heat pumps are already using ammonia, which is efficient and environmentally friendly. This will put the manufacturer in a favorable position.

We became aware of this as we were looking for a heat pump with low Global Warming Potential (GWP) for a project. Sabroe uses ammonia (NH3) in particular as a refrigerant in its products, a natural substance with excellent thermodynamic properties that enable it to achieve high temperatures. Ammonia has a GWP of zero, meaning that when released into the atmosphere, it does not contribute to global warming. Moreover, ammonia is a naturally occurring gas and does not require large amounts of fossil fuels in its production, leading to further reductions in its CO2 footprint.

But why is GWP so important to us? GWP is a measure that assesses the potential of a given amount of a greenhouse gas to cause global warming, compared to the same amount of carbon dioxide. By using a refrigerant with a GWP of zero, the user contributes to minimizing the climate impacts of his installations.

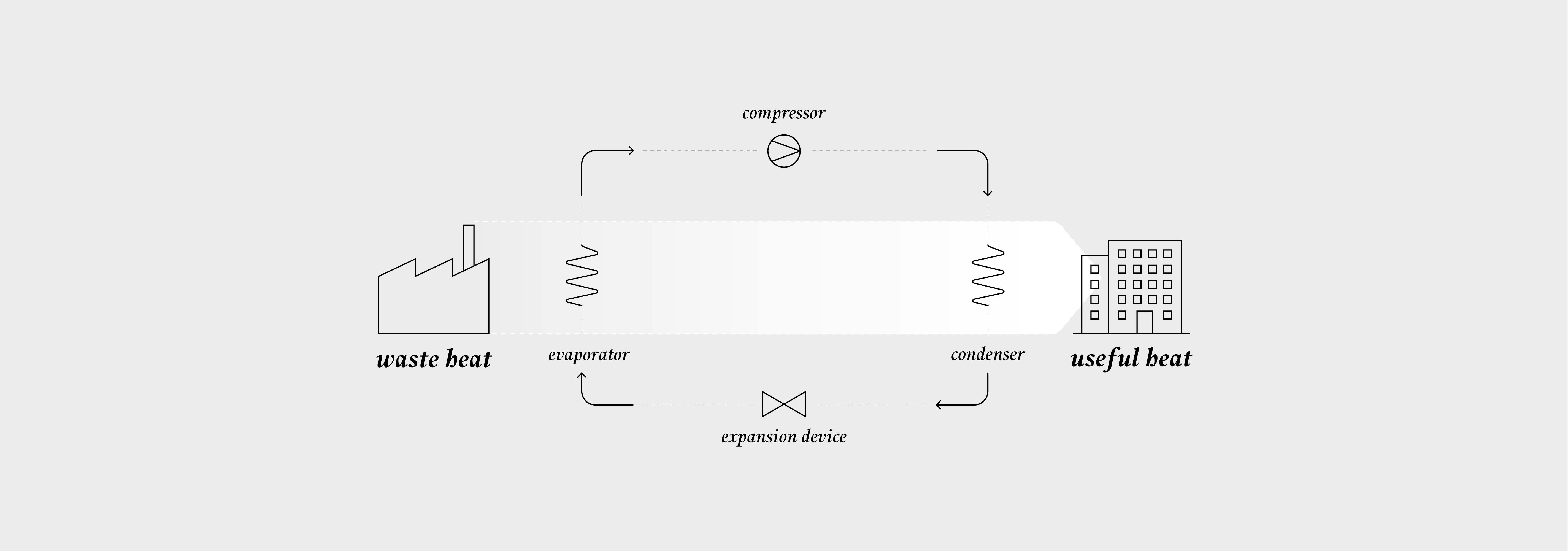

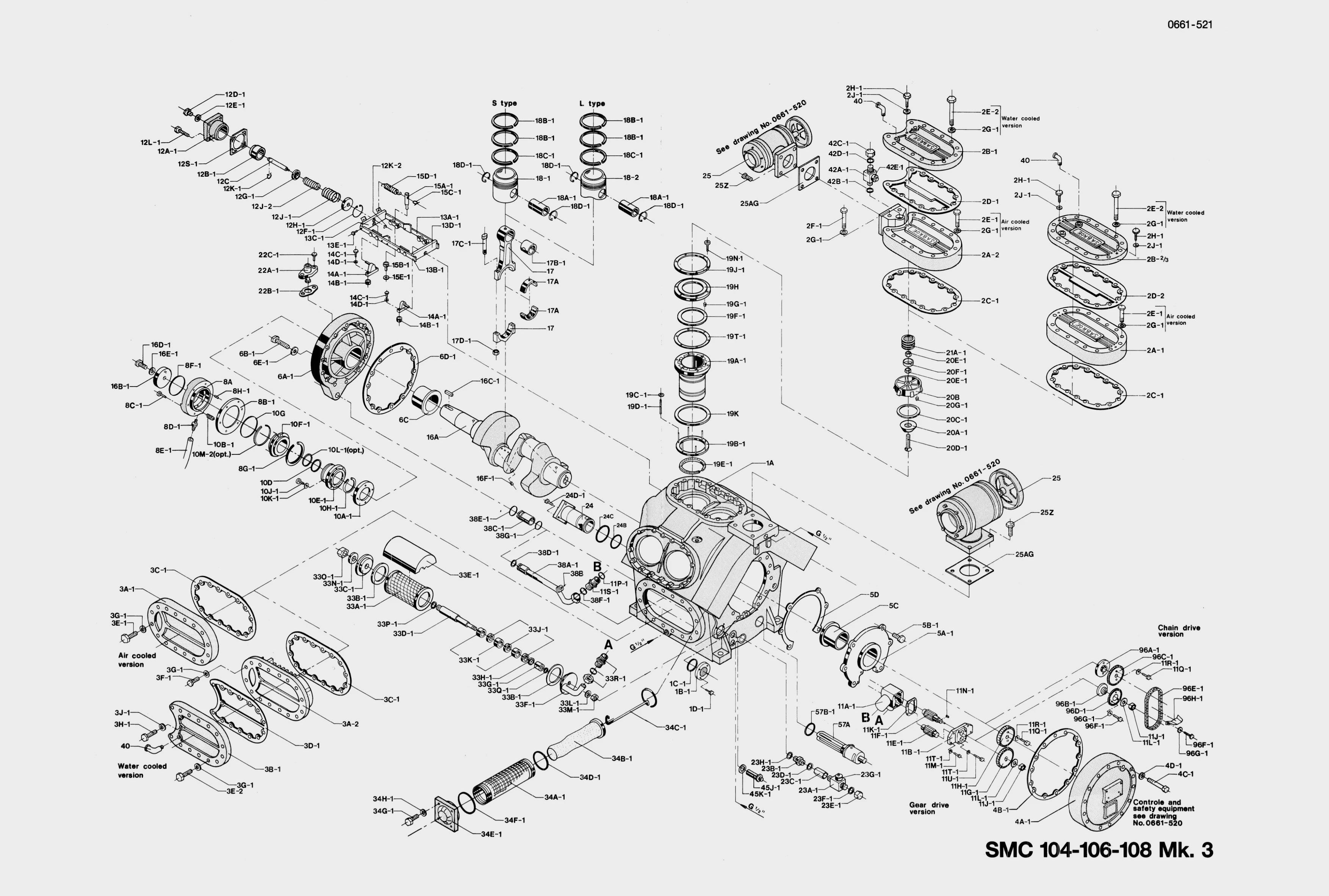

The cycle that the refrigerant goes through in the heat pump is similar to that of a refrigerator, only that the inside and outside are reversed. While the refrigerator takes heat energy from the stored food and leads it to the outside to the back wall, the heat pump absorbs heat energy from the environment and "pumps" it into the building and onto a higher temperature level. The “pumps” in Sabroe's heat pumps look like car engines with cylinders, whose camshaft is coupled to an extreme electric motor.

These massive engines elevate waste heat to temperatures of up to 120°C, making them ideal for applications such as district heating. With their advanced technology, they utilize the process or waste heat from industry, which would otherwise be wasted and released into the atmosphere, and turn it into usable heat for homes and businesses.

Brian Gaughan, the head of equipment sales, emphasized the durability and efficiency of their heat pumps: “I'm an engineer, not a salesman. However, our heat pumps are designed to work reliably and efficiently for decades. They utilize waste heat, which would otherwise be wasted, to generate heat in an environmentally friendly way. This engineering achievement is climate protection in action, and that's easy for me to explain to our customers.”

The Sabroe team has recognized the potential of high-temperature heat pumps and is focusing on exploiting this on a large scale. A central point here is the ability of heat pumps to use existing infrastructures and utilize waste heat sources that would otherwise remain unused. For example, waste heat produced in factories is used, but other sources such as nearby rivers and lakes, ambient air, soil, process air, wastewater, or flue gas from industry and trade can serve as low-temperature sources.

By reusing waste heat that would normally go unused, they actively work to reduce energy consumption and thus minimize the environmental impacts of their products. They are helping to accelerate the transition to a green economy by demonstrating that sustainable heat production is both practical and economically feasible.

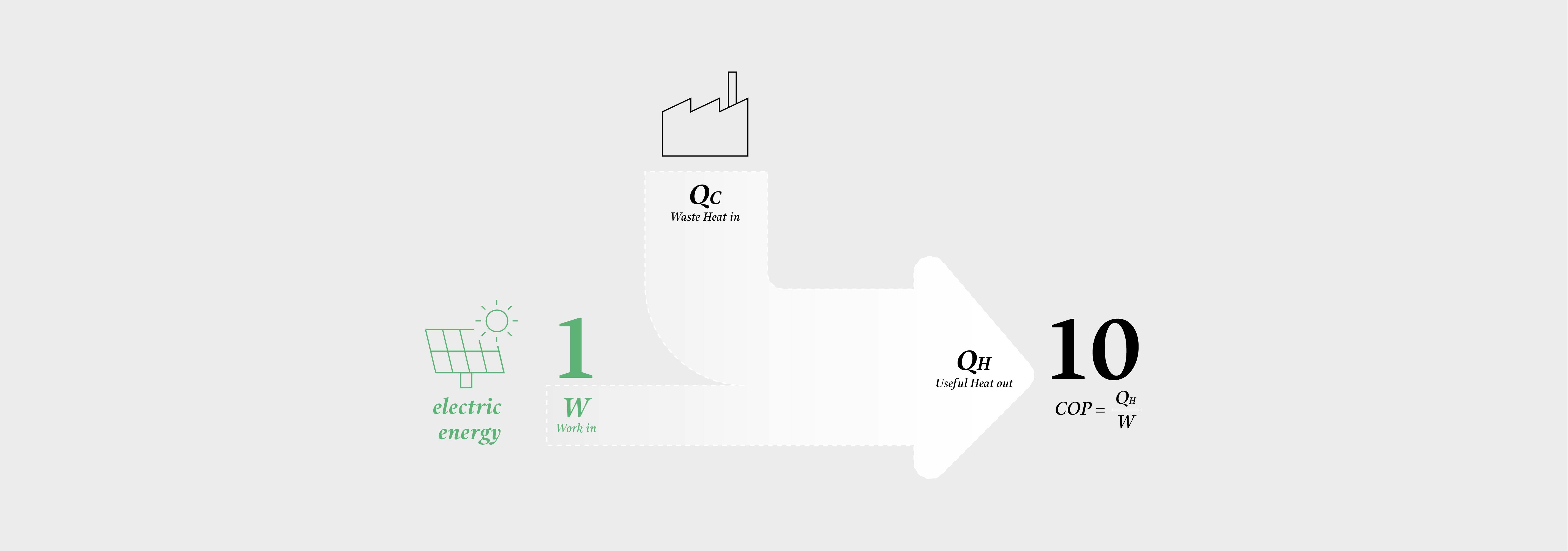

During our visit to the 10 MW (mega Watt) district heating station near Aarhus, we observed impressive results. The Sabroe heat pumps used at the station achieved an average COP of 10. COP stands for "Coefficient of Performance" and is a measure of the efficiency of a heat pump. The COP indicates how much usable heat a heat pump can produce from a given amount of driving energy (usually electricity). For example, a COP of 3 would mean that for 1 unit of electricity consumed, 3 units of usable heat are produced.

For the district heating station near Aarhus, this means that each unit of electricity used produces 10 units of usable heat. This is an outstanding result and shows the high performance potential of heat pump technology. It also underscores why using heat pumps to generate district heating can be an important step in improving energy efficiency and reducing greenhouse gas emissions.

What was remarkable about the visit was the realization that there are indeed possibilities to replace fossil fuels as an energy source with low-emission alternatives. The example of district heating is particularly interesting. Coal and gas are still an important energy source for district heating, but replacing these with powerful heat pumps sounded impossible to us until then. However, by utilizing low-temperature sources at power plant locations and generating high temperatures, district heating can be achieved with heat pumps. By utilizing low-temperature sources at power plant sites and generating high temperatures, district heating can be efficiently and sustainably provided with heat pumps.

According to calculations, the use of large-scale heat pumps could reduce CO2 emissions by almost 80 percent compared to fossil fuels. In a future where the power supply is entirely based on renewable energy, these emissions could even be reduced by 100 percent.

For this, we need heat pumps that are capable of reaching particularly high temperatures. This is crucial for district heating supply, as many of the existing German district heating networks for example operate at temperatures of 90 to 120 degrees Celsius. In Denmark, we were able to see that there are products that can efficiently deliver these high temperatures.

Unfortunately, we were not allowed to take pictures in the Sabroe factory. But I can assure you that the work being done there is truly impressive. The production methods are very traditional, heavily influenced by the craftsmanship of the machine builders. Each heat pump is a tailor-made unit, adapted to the specific requirements of each customer. This individual approach means that there is no assembly line work, which gives the factory an almost artisanal atmosphere.

The ability to disassemble their high-temperature heat pumps means that they can not only be repaired and maintained but can also be recycled at the end of their life cycle. This longevity and reusability are key aspects of the circular economy and support the sustainability goals of a green economy.

A particular highlight was the test stations- one of Europe biggest test station our tour guid highlighted. Each individual heat pump is thoroughly tested here before it is shipped. This rigorous testing process ensures that each machine leaving the factory meets the manufacturers high quality standards. Overall, the visit to the Sabroe factory was a fascinating experience that underscored the quality and high technological standard of Sabroe's heat pumps.

We look forward to continuing to monitor their technology advancements. As far as sustainable energy generation is concerned, the district heating station we saw is setting high standards.

Back