Design For Disassembly

Design for disassembly – or simply Dfd - is one of the key strategies that the circular economy is based on. It is a principle that allows the reuse of materials and components in the built environment without any significant loss of quality. This means that the materials can be used again and again in several life-cycles for different buildings. But how is it possible to use building materials like a kit of parts?

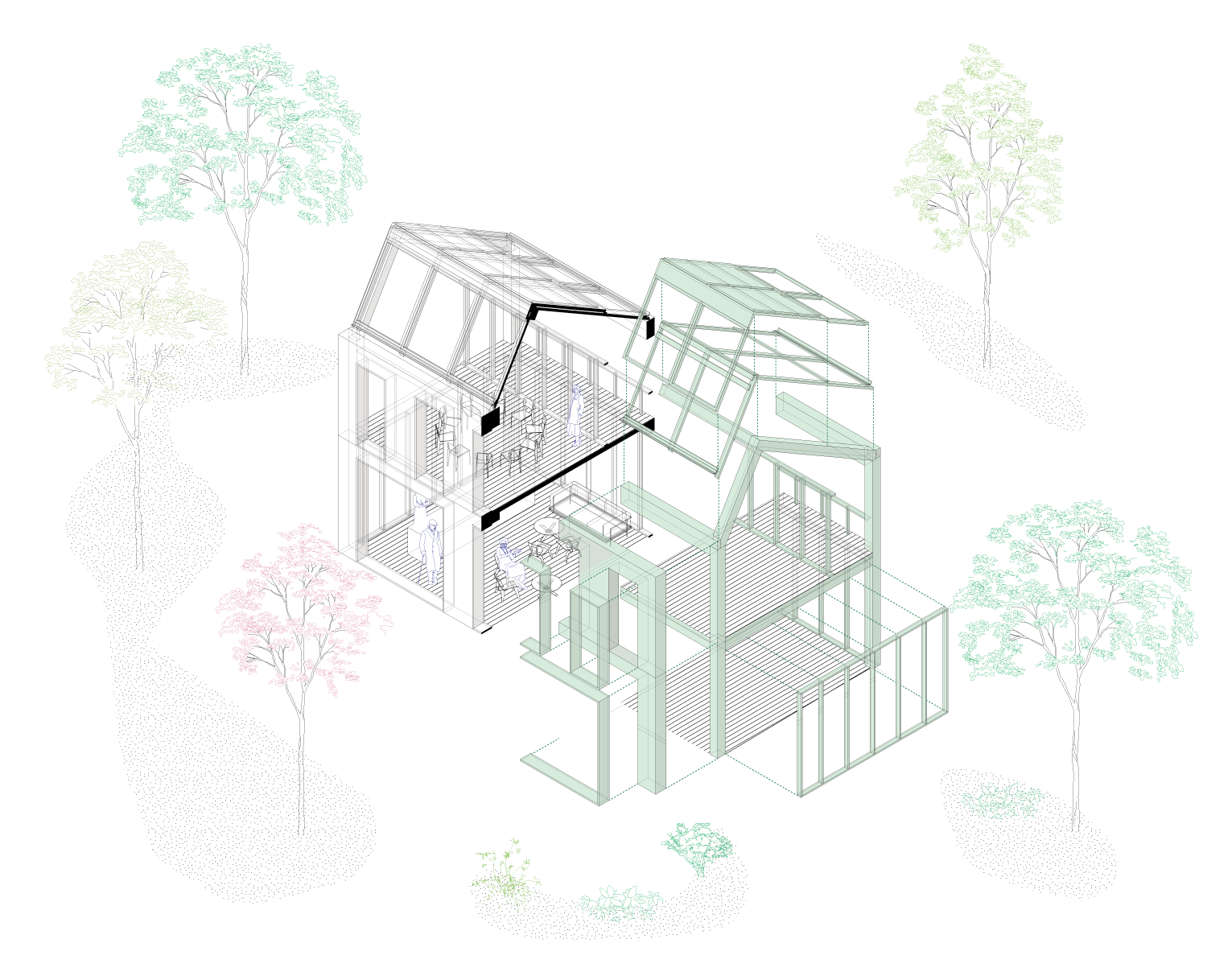

The answer is simple. Building parts need to be designed in a way to allow for reversible connections. These can be screw or clamp connections or any other principle that forms a reversible joint. Traditional building techniques are geared towards constructing a static and permanent structure, that is tailor made for one purpose. It is an approach that is only focused on the creation of one specific building with little consideration to what happens to the construction material after the use of the building has ended. Design for disassembly comes into play even before the construction has begun. As the name says, it is a design strategy that focuses on assembly and disassembly to the same degree.

LEGO can provide some insights to architecture on how to apply Dfd principles. The game is a perfect example of deconstruction of built objects. Its uniformity of plug-in slots allows – whilst following a set of rules - the creation and demolition of diverse structures. The book “Lego and Philosophy” points out three key characteristics of the brick pieces: versatility, backwards compatibility and ease of dissassembly. Within the Dfd framework, versatility means that elements may accept connections to a wide range of other materials. Backwards compatibility allows newly fabricated components to be capable of joining previously created structures. And ease of dissassembly frees the parts for further reuse without material damage. Operations present in the game like convertibility, addition and subtraction should be part of the Dfd vocabulary.

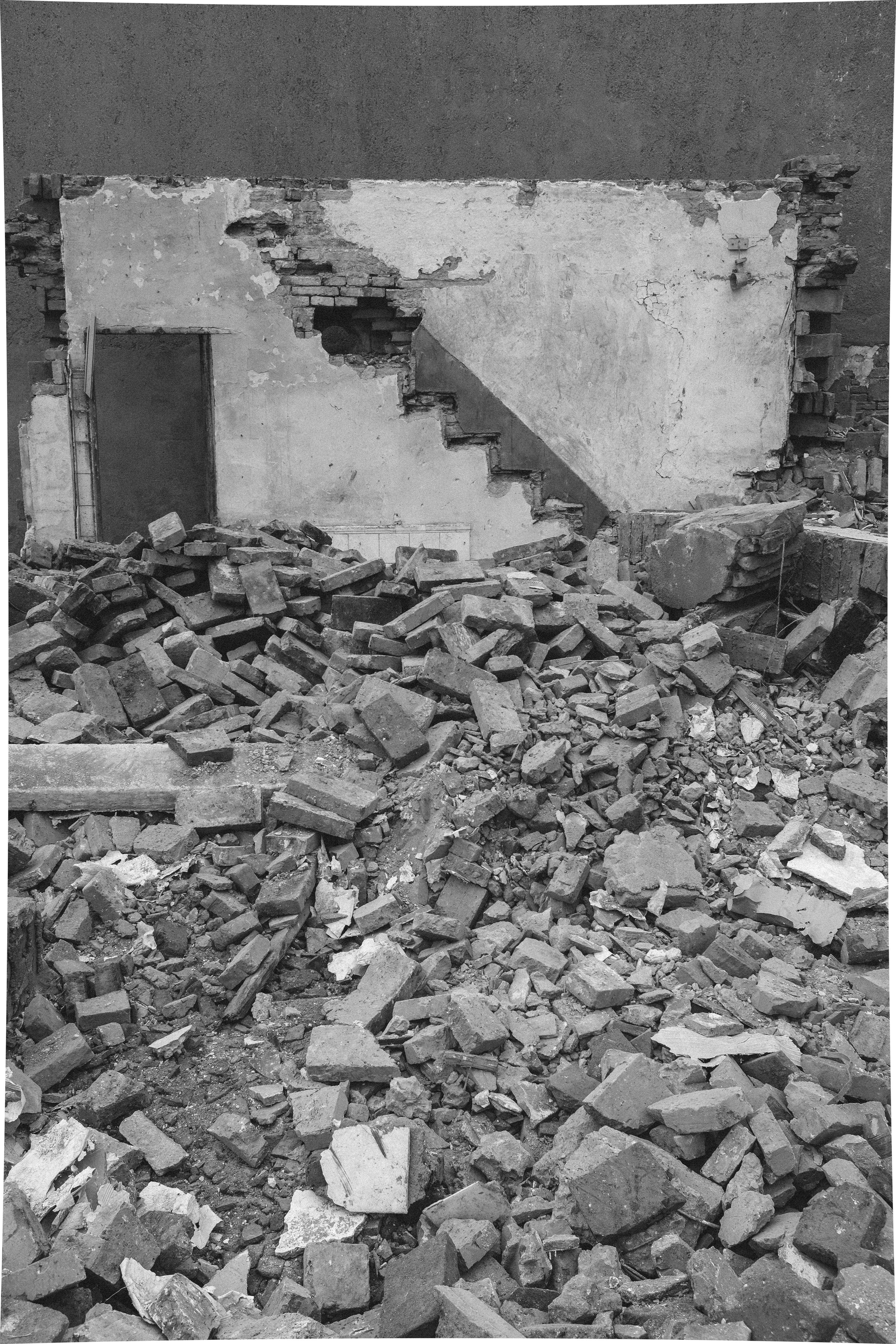

Specific materials and building techniques are more suitable to realize a building structure that is dismountable. The most unsuitable techniques are to choose mineral building materials like concrete and brick, because the inherent nature of these materials is it to form permanent bonds. Very efficient construction techniques are timber or steel structures because they are typically joined together with screws. In recent years the emergence of cross-laminated-timber as a structural material led to an increase in its use for large scale structures, as the material is very stable and lightweight at the same time. It is very economic to use CLT elements in design for disassembly because they can not only be mounted together with screws but also the material comes from a sustainable source. With steel elements there is always the initial production process which has a larger carbon footprint than the production process of the same module built in CLT.

It is very important for a long-lasting lifespan of the building modules that they are produced according to high quality standards. If we consider that the life cycle of a building lasts several decades and the materials are designed to be used in several buildings, it is clear that the building materials will need to be resistant against wear and tear as much as against corrosive influences. It makes sense to construct a building with different material lifespans in mind, as for example all materials which are used as outer surfaces will last less long than materials that are used in the inner structure of the building, and which therefore need to be replaced earlier.

Design for disassembly will become increansingly important in the future, as flexibility and adaptability of building structures become a bigger priority. It is a facilitator for circular architecture and thus one of the main tools in the change towards a more sustainable construction industry. Dfd aims to convert the current linear construction system into a closed one. Ultimately architecture could become a factory of itself, if every single element is flexible enough to become part of another structure. In this scenario, the construction and waste management stages are so connected that the obsolescence of a building becomes an opportunity for the creation of a new one. This situation may seem too far-fetched, however some Dfd principles are already integral to many fields of architecture, such as exhibition pavillions, temporary event structures, military facilities and humanitarian camps. Although linked to ephemeral architecture these examples should provide some basis for expanding the principles to more permanent fields of architecture.

* see: Brad Guy, Nicholas Ciarimboli; Design for Disassembly for the built Environment - A guide to closed-loop Design and Building, 2017

Back